Test & Inspection

Test & Inspection

The true cost of calibration testing often stays hidden, escaping scrutiny in operational and maintenance metrics.

Read More

Test & Inspection

Circuiting Progress: Academics to Analog Design Engineer

Analog design creates a seamless connection between the analog world and modern digital technology.

April 29, 2025

Test & Inspection

Portable Hardness Test Methods and When to Use Them

The most important step is to familiarize yourself with the limitations of the test method to avoid inaccurate results.

March 16, 2025

Test & Inspection

Advancements in Hardness Testing: Heatmapping and the Power of AI-Indentation Evaluation in the Metals Industry

An exciting addition to hardness testing is the integration of AI-based indentation evaluation, which enhances the precision and efficiency of hardness mapping.

February 15, 2025

Test & Inspection

Energy Costs, EV Growth Drive Changes in Leak Testing Methods

The scope of leak testing applications continues to expand beyond traditional industries.

January 27, 2025

Test & Inspection

Universal Testers: The Greatest Thing for Slicing Bread?

Documenting material properties is often a key factor in quality control and R&D divisions.

January 24, 2025

Test & Inspection

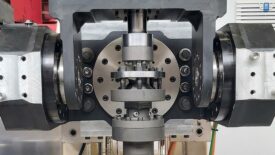

Noise Vibration Harshness (NVH) Quality Inspection

To meet the new torque and rpm requirements, the gears for electric drives must be designed with tighter manufacturing tolerances, especially in terms of lead and profile characteristics.

January 2, 2025

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

b002.jpg?height=168&t=1738009418&width=275)