George Schuetz

George Schuetz has been employed with Mahr Inc. for over 40 years in the metrology business. During that time, he has worked in the applications areas for Precision Gages, Special Gage Designs, Surface and Form Gaging working to solve customer's specific gaging problems.

Over the years, he has contributed articles to magazines including Quality in Manufacturing, Quality Digest, Quality Magazine, and is a monthly contributor to Modern Machine Shop. He has also written a book entitled Quality Gaging Tips, a compilation of modern machine shop tips.

Presently George is responsible for Precision Gage Product management at Mahr Inc. For more information, call (401) 784-3392, email [email protected] or [email protected] and visit www.mahr.com.

ARTICLES

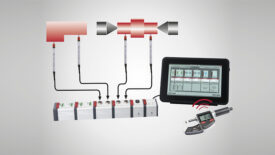

Enhancing Manufacturing Efficiency with Integrated Wireless Gages and Quality 4.0 Principles

A New Touch for Handheld Gaging

Is it a Digital Caliper – or a Swiss Army Knife?

Air Gaging Moving Forward Faster Than You Think

How to Measure Big IDs and ODs

Handheld Gaging: It All Comes Down To The Touch

It is Never Too Late to Teach an Old Custom Gage New Tricks

Modern Gaging Trends: Technology Evolves to Meet the Needs of Today’s User

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing