Manufacturing Software

New Software Assesses, Validates Stamping Processes

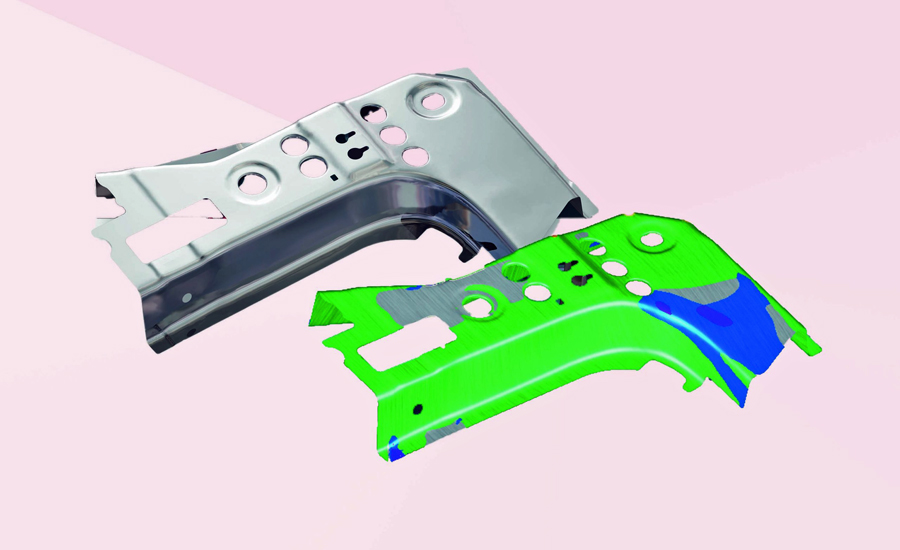

Simulation software lets engineers evaluate and fine-tune stamping lines before dies are cut or parts are produced.

Image courtesy of AutoForm Engineering GmbH

PFÄFFIKON, Switzerland—AutoForm Engineering GmbH, a supplier of software for stamping and body-in-white (BiW) assembly processes, has released a new version of its AutoForm Forming R12 software. This version provides new capabilities and enhancements for the sheet metal forming process, in particular for the feasibility and validation phases of stamping processes.

An updated mesh refinement strategy allows for a more realistic prediction of the severity, size and number of wrinkles during and at the end of the forming process. The software also enables engineers to consider not only the maximum press forces but also their distribution. They can now better ascertain whether the press is capable of appropriately closing the tools and thereby ensure that part production runs smoothly.

In addition, AutoForm Forming R12 offers various solver improvements, such as the option for parallel execution on 16 cores for faster simulation and an increased maximum number of elements particularly supportive for larger parts and parts with very fine structures. The software also offers various TriboForm enhancements, including expanded libraries especially important for the tryout phase. AutoForm Forming R12 enables engineers to quickly and easily evaluate process feasibility.

AutoForm Forming R12 brings new capabilities that are important for the process validation phase. Spring-back compensation is now facilitated by an improved smoothing control option, which allows engineers to adjust smoothing factors to achieve the desired surface quality. The enhancements in AutoForm Die Designer Plus are also important for process validation, because they facilitate the creation and compensation of high-quality surfaces within the AutoForm environment. The latest release also brings new options for compensation of elastic tool deflection, which can lead to a greater reduction in the number of tryout loops, rejects and press downtime in production.

“With AutoForm Forming R12, we offer our users a range of new features and enhancements that are important for the sheet metal forming process chain,” says Markus Thomma, Ph.D., chief marketing officer of the AutoForm Group. “Process designers can achieve better part and process designs, improved design quality and more reliable long-term design performance.”

For more information, click www.autoform.com.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!