Vision & Sensors | Optics

Precision in Optical Metrology: Telecentric vs. Endocentric Imaging

Choosing the right optical setup is critical to minimizing errors and ensuring that dimensional measurements are repeatable and reliable.

Image Source: banjongseal324 / iStock / Getty Images Plus

In industrial quality control and measurement applications, optical metrology plays a critical role in ensuring precision and repeatability. Accurate dimensional measurement of parts, components, and assemblies is essential in industries such as automotive, electronics, and medical devices, yet machine vision systems face challenges due to physical limitations. Unlike the human eye, which intuitively perceives edges, cameras rely on sensors with finite pixels, making edge detection dependent on pixel resolution. This limitation underscores the importance of selecting appropriate optics.

Two main imaging approaches - telecentric and endocentric optics - offer different advantages and limitations depending on the application. This article examines their key differences, strengths, and trade-offs to help professionals make informed decisions.

Telecentric imaging: Ensuring precision

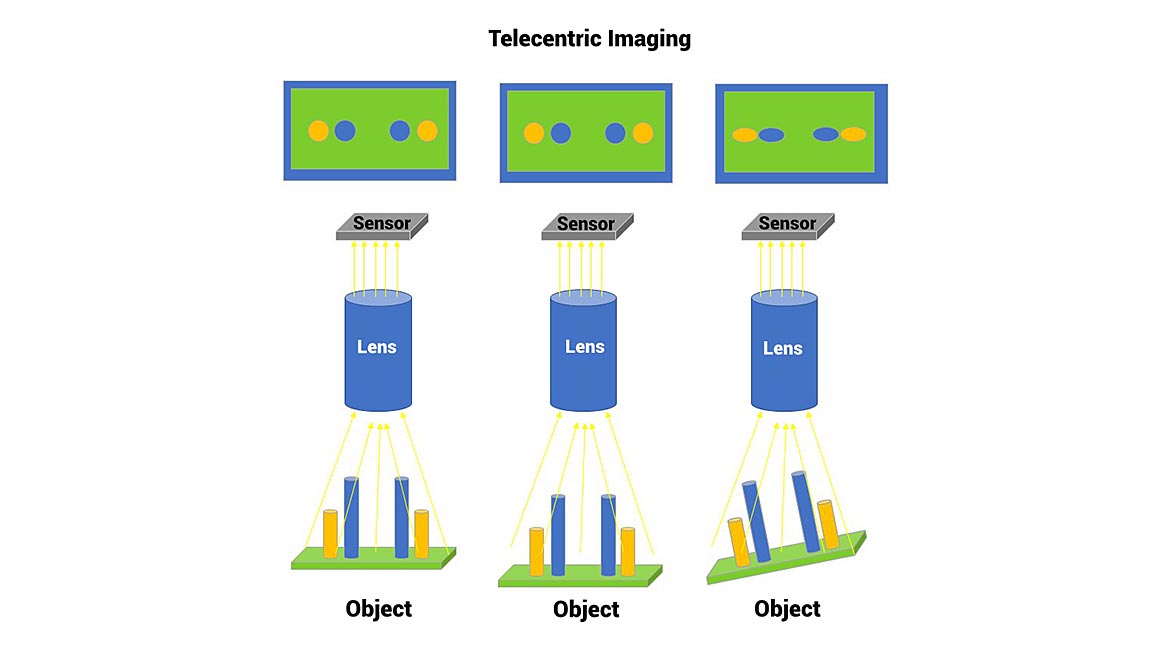

Telecentric lenses are designed so that light rays are parallel to the optical axis, eliminating perspective distortion. This design ensures consistent image scaling along the axial direction (Z-axis), which means that measurements remain accurate even if the distance of the object from the camera varies slightly. For example, the distance between two holes is consistently measured regardless of small positional shifts. However, these lenses can be bulky and expensive, especially for larger fields of view. Their size and weight can be a challenge in dynamic applications such as robotic systems.

Endocentric imaging: A cost-effective alternative

Endocentric or conventional lenses present a perspective-based image where object size varies with distance from the camera. While this presents measurement challenges due to perspective distortion, endocentric lenses are more compact and affordable. With proper calibration and software correction, they can provide satisfactory measurement accuracy, especially in applications where small variations are acceptable.

Balancing accuracy and practicality

The choice between telecentric and endocentric imaging depends on the specific application requirements. Telecentric lenses offer unparalleled accuracy, making them ideal for high-precision tasks. Conversely, endocentric lenses provide a practical solution when budget and space constraints are factors, and the highest accuracy is not critical.

In summary, understanding the distinct advantages and limitations of both telecentric and endocentric imaging systems enables professionals to choose the most appropriate approach for their optical measurement needs.

Challenges in optical metrology

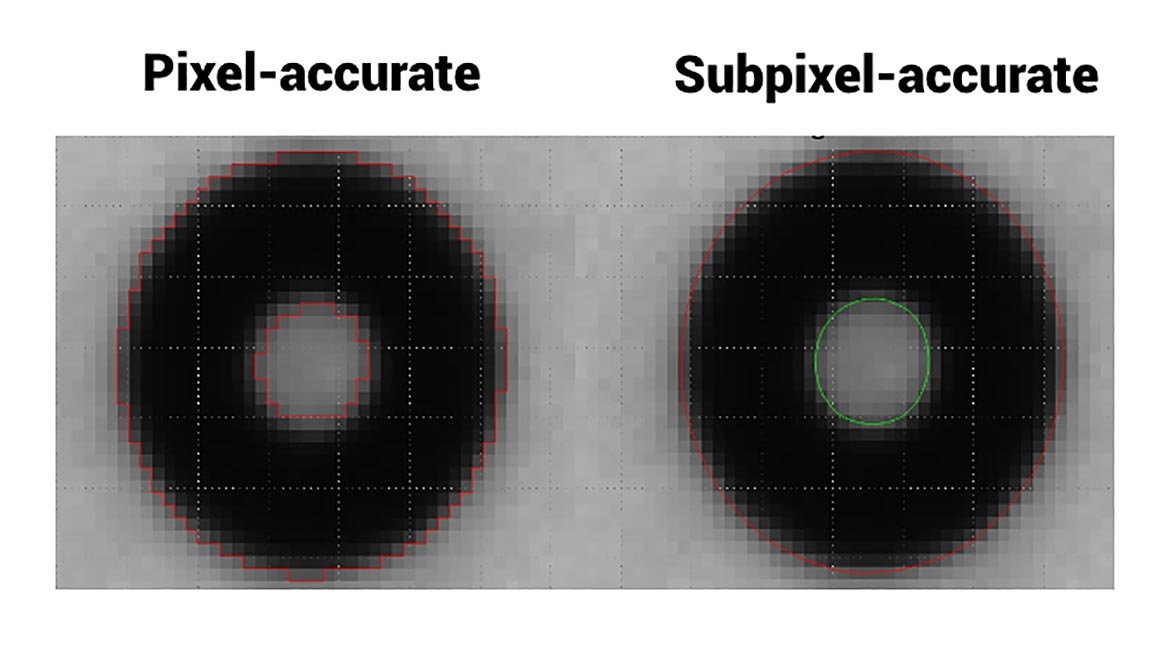

When measuring objects optically, the accuracy of edge detection is one of the biggest challenges. Unlike human vision, which can intuitively recognize edges even in complex environments, cameras rely on sensors with a finite number of pixels.

The accuracy of the measurement is therefore limited by:

- Pixel resolution: The ability of the sensor to distinguish small details depends on the size and number of pixels.

- Edge detection algorithms: Software must compensate for limitations in contrast, noise, and blur to correctly define object boundaries.

- Optical distortions: The choice of lens can introduce perspective errors or magnification inconsistencies that affect measurement accuracy.

Choosing the right optical setup is critical to minimizing errors and ensuring that dimensional measurements are repeatable and reliable.

Telecentric imaging: High-precision measurement

Telecentric lenses are a special type of optical system designed so that light rays entering the lens travel parallel to the optical axis. This unique property eliminates perspective distortion, making telecentric optics ideal for precise dimensional measurement.

Advantages of telecentric imaging

- Elimination of perspective errors: Unlike standard lenses, telecentric lenses ensure that objects appear the same size regardless of their distance from the camera. This is critical when measuring dimensions such as hole distances, widths, and diameters.

- Consistent measurement scaling: Since magnification does not change with depth, measurements remain accurate even if the object is not perfectly aligned.

- High edge definition: Because telecentric lenses reduce distortion, they provide sharper, more reliable edge detection, leading to improved accuracy in metrology applications.

- Minimized parallax effect: Objects with depth, such as drilled holes, are imaged without the parallax error seen with standard lenses, ensuring accurate dimensional analysis.

Limitations of telecentric optics

- Size and weight: Telecentric lenses are physically larger and heavier than standard lenses, making them unsuitable for space-constrained environments or mobile applications (e.g., robotic vision).

- Higher cost: Due to their complex optical design, telecentric lenses are significantly more expensive than conventional endocentric lenses. This cost may not be justified for all applications.

- Limited field of view: The field of view (FOV) of telecentric lenses is generally smaller than that of standard lenses, requiring careful selection to match the size of the object to be measured.

Best use cases for telecentric imaging

- High-precision measurement of finished parts

- Inline inspection systems where small deviations matter

- Quality control applications requiring sub-pixel accuracy

- Optical measurement of hole spacing, gears, or PCB components

Endocentric imaging: A flexible and cost-effective solution

Endocentric lenses, or standard camera lenses, function similarly to human vision—objects appear smaller as they move further from the camera. This introduces perspective distortion, where objects closer to the lens appear larger than those further away.

Advantages of endocentric imaging

- Compact and lightweight: Standard lenses are smaller and easier to integrate into space-constrained environments, including robotic applications.

- Lower cost: Compared to telecentric lenses, endocentric optics are significantly less expensive, making them an attractive option for cost-sensitive applications.

- Larger field of view: Standard lenses allow for larger fields of view, making them ideal for capturing larger objects or scenes.

- Flexible working distances: Unlike telecentric lenses, endocentric optics can adjust focus at different object distances, providing greater adaptability.

Limitations of endocentric optics

- Perspective distortion: Objects appear different sizes depending on their distance from the camera, leading to potential measurement inaccuracies.

- Magnification variability: Because magnification changes with object position, consistent measurements require precise calibration and software correction.

- Edge ambiguity: Lack of telecentricity can lead to measurement errors, especially when dealing with parts that vary in depth.

Best use cases for endocentric imaging

- General machine vision applications where slight measurement deviations are acceptable

- Object classification and defect detection

- Applications requiring working distance flexibility

- Large area inspections with moderate measurement accuracy

Choosing the right optical solution

When selecting between telecentric and endocentric optics, decision makers must consider the specific requirements of their application. A comparative summary is provided below:

Feature |

Telecentric imaging |

Endocentric imaging |

|

Perspective distortion |

None (parallel light) |

Present (size varies with distance) |

|

Measurement accuracy |

High (ideal for metrology) |

Moderate (requires calibration) |

|

Cost |

Higher |

Lower |

|

Field of view |

Smaller |

Larger |

|

Size & weight |

Bulkier |

Compact |

|

Best for |

Precision measurement |

Flexible, cost-sensitive applications |

For applications where precision is non-negotiable - such as gaging, metrology, or quality control of critical components - telecentric lenses are the best choice despite their cost and size. On the other hand, when space, budget, or flexibility are key concerns, endocentric lenses can still provide adequate performance with proper calibration and software compensation.

Conclusion

Selecting the right imaging optics is a critical step in ensuring accurate and reliable measurements in machine vision applications. Telecentric imaging provides superior measurement accuracy by eliminating perspective distortion and ensuring consistent scaling. However, endocentric imaging offers a more practical and cost-effective solution for applications where the highest level of accuracy is not required.

By understanding the strengths and limitations of each approach, engineers and decision makers can choose the best optical solution for their specific needs—balancing accuracy, cost, and practicality. Whether implementing high-precision measurement in quality control or developing a flexible vision system for automation, the right optical setup will have a significant impact on performance and reliability.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!