Measurement

Microns Over Miles: Pushing the Boundaries of Alignment

Survey and alignment techniques used to upgrade the Advanced Photon Source

The Advanced Photon Source, a U.S. Department of Energy Office of Science User Facility, is in the process of a major upgrade, transforming it into one of the most advanced synchrotron light sources in the world. (Credit: Argonne National Laboratory/J.J. Starr.)

The Advanced Photon Source (APS) at the U.S. Department of Energy’s (DOE) Argonne National Laboratory (ANL) is one of the world’s leading X-ray light source facilities, enabling groundbreaking research in fields such as materials science, biology, and chemistry. In a typical year, more than 5,500 scientists from around the world travel to Argonne to use the extremely bright, focused X-ray beams produced by the APS. After more than 25 years of nearly continuous use and advancements in technology, the facility was ready for a major update.

Following years of development and planning, Argonne is in the process of completing an $815 million upgrade with funding from the DOE, transforming the APS into the brightest synchrotron X-ray facility in the world. After a yearlong shutdown to remove the original electron storage ring and replace it with a new multi-bend achromat lattice, the APS can now produce X-ray beams up to 500 times brighter than before. The horizontal emittance of the electron beam used to generate the X-rays was reduced from 3100 picometers-radians (pm·rad) to 45 pm·rad, resulting in smaller, more focused X-ray beams. (A picometer is a trillionth of a meter.) This upgrade is not just a technical milestone but has also transformed the APS into a cutting-edge research tool with unparalleled precision.

Such advances do not happen overnight. They are the result of tireless efforts by hundreds of people working together under tight timelines. For the team at Argonne, the challenge wasn’t just how to upgrade the APS but how to do so safely and in a way that ensured that world-class research would resume as soon as possible.

The Need for Precision: Alignment of the APS Accelerator

The APS storage ring consists of an array of electromagnets arranged along a 1,104-meter-circumference ring. (That’s nearly two-thirds of a mile around.) Its job is to circulate electrons at nearly the speed of light using electromagnetic energy. The magnets must be aligned with extreme precision, as even slight misalignments can degrade the quality of the X-ray beams produced by the accelerated electron beam.

Processes for magnet fiducialization, module assembly, and module installation and alignment were designed to maximize efficiency while meeting strict tolerance specifications. For example, the tolerance for magnet-to-magnet alignment within a module is 30 micrometers (μm), while module alignment within the storage ring lattice must be within 100 μm. (A micrometer is one millionth of a meter.)

To achieve this level of precision, the team at Argonne developed specialized survey and alignment tools and techniques. These methods were intended to optimize resources and minimize the downtime required for the installation of the new machine.

The storage ring is not a true circle but a 520-sided irregular polygon. The electron beam releases high-brightness photons at each bend in the track. The ring contains 1,321 magnets, along with vacuum systems, radio frequency systems, and diagnostic components. Achieving the required precision in aligning the components of the APS storage ring and the beamlines demanded extensive planning and preparation. Some of the most effective techniques that contributed to our success included:

-

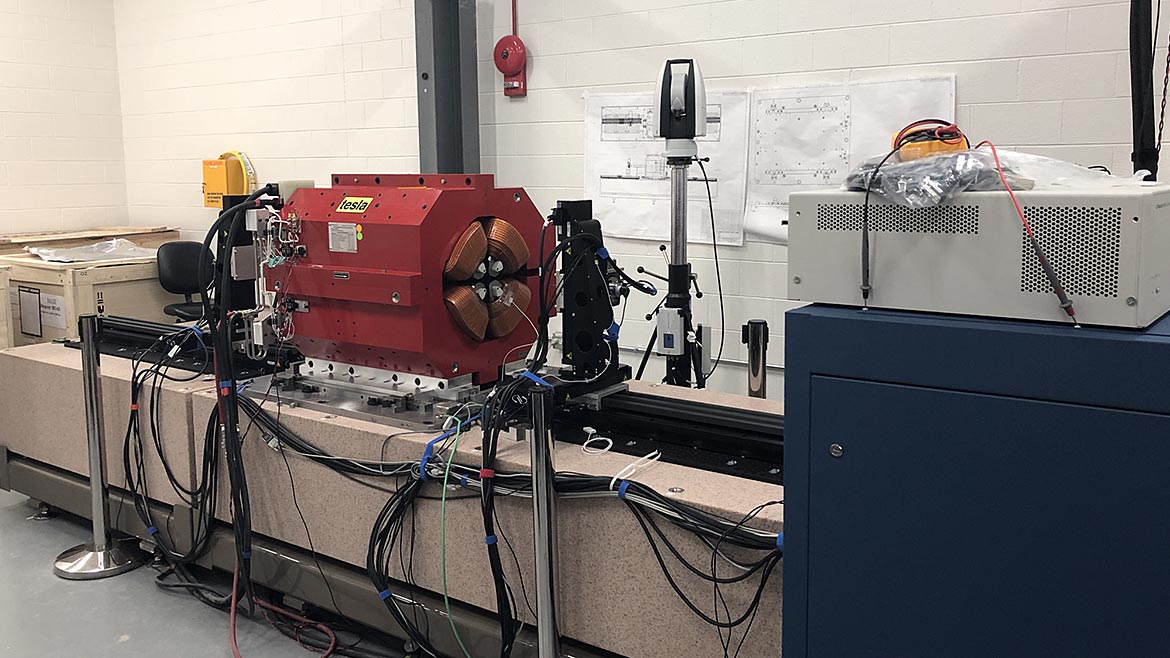

Conducting ultra-precise magnet measurements

The first step in building the accelerator was a four-year effort to measure 1,190 of the 1,321 electromagnets. Precision magnet fiducialization laid the foundation for achieving alignment within the strict tolerance specifications. We developed a novel process that used a rotating taut wire and a laser tracker to reference the magnetic centers to external fiducial points, with a measurement uncertainty of 6-μm root mean square (RMS). This precision at the individual magnet level enhanced our confidence in meeting the overall alignment tolerance for module assembly and installation into the ring. -

Using scripts and automation to optimize assembly and alignment

Scripting and automation were crucial to installing the new machine within a one-year timeframe. Multiple software tools were integrated to streamline the process. Tasks such as data acquisition, optimal shim placement, coordinate transformations, point renaming, quality evaluation, and data analysis were automated to improve efficiency, ensure consistency and minimize errors. Sophisticated measurement planning tools were developed within metrology software to automate measurement and data processing for module assembly and installation. Leveraging available computing technology to enhance process efficiency was a key factor in our success. -

Designing a modular assembly process

The APS Upgrade utilized a modular assembly process to efficiently achieve precise alignment. Magnets were pre-aligned in groups on 200 interchangeable modules at an off-site facility. Individual QR codes on each magnet enabled quick retrieval of fiducial data for precise alignment. Alignment relied on machining tolerances, and we used a custom software to prescribe shim placements, ensuring accurate positioning. Laser tracker surveys validated the alignment, with additional shimming performed as needed to improve results. Vacuum and diagnostic systems also relied on machining tolerances and pin stops for alignment, significantly reducing assembly and alignment time while maintaining the micrometer-scale precision critical to performance. -

Using the latest metrology techniques to rapidly establish a control network

Alignment of large-scale facilities requires a high-precision control network. Advances in laser tracker and software technology have considerably reduced the time needed to conduct large-scale control surveys. Following the removal of the original APS storage ring, a new control network was established in just three weeks by a team of two technicians using a single laser tracker. The team measured 1,296 monuments, or precision reference points, from 240 laser tracker positions, achieving an average point uncertainty of 31 μm and a maximum of 59 μm.

The storage ring network is the primary control for the facility. Multiple secondary networks were also established for beamline alignment. These secondary networks are tied to the primary control and now include more than 5,500 monuments to aid in ongoing alignment. Employing state-of-the-art metrology techniques and software enabled us to establish the control networks in a remarkably short time frame. -

Using specialized adjustment tools for module installation

At the time of installation, the largest modules – each weighing 20,000 kg – were installed first and positioned using custom hydraulic A-frame adjustment systems. After grouting the module bases, the upper module magnet arrays were precisely aligned using three vertical and three horizontal adjusters. Smaller bridge modules followed, aligned with similar systems. Scripted measurement steps and automated data processing ensured quality results. All module alignment was accomplished using laser trackers.

The original APS ring was shut down and removed beginning in April 2023. By March 2024, all new modules had been installed and aligned. The radial alignment result was 19-μm RMS, and vertical alignment was 30-μm RMS. The new machine was started up in April 2024. Beam path length, derived from radiofrequency measurements, showed only a 0.82-mm deviation over 1,104 meters. Horizontal beam emittance measurements set a new world record, surpassing the previous record achieved at the European Synchrotron in France.

Aligning beamlines for exacting research

The completion of the new storage ring was a major milestone, but our focus has now shifted to realigning over 70 X-ray beamlines, the highly specialized optical systems that transmit and focus light for scientific experiments.

Each beamline at the APS includes an array of optical elements, such as collimators, mirrors and detectors. These components must also be precisely aligned to ensure the highest quality experimental results. Even minor misalignments can reduce the beam’s intensity, compromising the quality of the research.

Unlike the storage ring, which involved interchangeable modules in a repeating pattern, each beamline has a unique geometry, making scripting and automation less effective. The alignment tolerance is more forgiving: ±250 µm for most components. Laser trackers, portable measurement arms, and optical instruments are used for beamline alignment. By the end of 2024, we commissioned more than 30 beamlines and expect to complete the remaining ones by mid-2025.

The continuing success of the APS Upgrade has been the result of years of meticulous planning, preparation and collaboration among multiple teams at Argonne. Installing more than 1,300 electromagnets, miles of cables, and thousands of additional components required careful coordination. This achievement would not have been possible without the extensive collaboration of Argonne physicists, engineers and technicians, along with numerous outside vendors. The project’s success relied on a shared goal: restoring the facility to full operation with enhanced capabilities to benefit users worldwide.

A key takeaway from the APS survey and alignment efforts is that precision and speed can coexist. By integrating cutting-edge technologies and developing workflows that leveraged the strengths of multiple tools, Argonne successfully executed complex, time-sensitive alignment tasks with minimal disruption to scientific research. This accomplishment sets a new standard for alignment in large-scale, high-precision facilities.

What’s next for the APS?

The APS upgrade is far from over. While the facility is now operational, it will continue to ramp up to its full capacity, with more beamlines coming online and additional features being integrated. More than 1,400 research proposals have already been submitted by scientists eager to explore the new capabilities, ensuring that the APS will remain at the forefront of groundbreaking scientific inquiry for years to come.

Further reading

A more comprehensive treatment of this topic is available here: https://indico.slac.stanford.edu/event/9126/contributions/10238/attachments/4632/12567/Jansma-IWAA-2024_Final_20240930.pdf

Updates to the Advanced Photon Source were made possible by the U.S. Department of Energy’s Office of Science. APS is a DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

0caf.jpg?height=200&t=1705603301&width=200)