Measurement

What is a “Higbee cut”? And Other Related Thread Terms

We are lucky in the metrology and gage manufacturing world to have access to standards maintained by ANSI, ASME, Mil, NIST, DIN, ISO, IEC and many more.

Image Source: Vermont Gage

In any industry there are always certain words, phrases, abbreviations, acronyms, and other nomenclature that are not always clear to those who are new to the field. This includes both experienced managers in new roles and new employees alike. In some cases, the knowledge of the existing team is tribal in nature. Meaning that they pass on the information as they have had it taught to them. If the information is correct and complete there are minimal issues. What happens when the information is incomplete or worse, wrong?

This is where the various industry standards and the committees that write and maintain them are a valuable resource to clear up many of these misconceptions. We are lucky in the metrology and gage manufacturing world to have access to standards maintained by ANSI, ASME, Mil, NIST, DIN, ISO, IEC and many more. Many of these industry standards have definitions of key words within the first few pages of their standards. In some cases, these standards committees have developed an industry specific dictionary type of standard for definitions. The ASME B1.7-2006 (R2021) "Screw Threads: Nomenclature, Definitions, and Symbols" is the dictionary for terms associated with threaded parts and gages.

Below are a few examples of thread industry specific terms that are frequently misunderstood. We will be using the definitions as specified by ASME for the terms in this article.

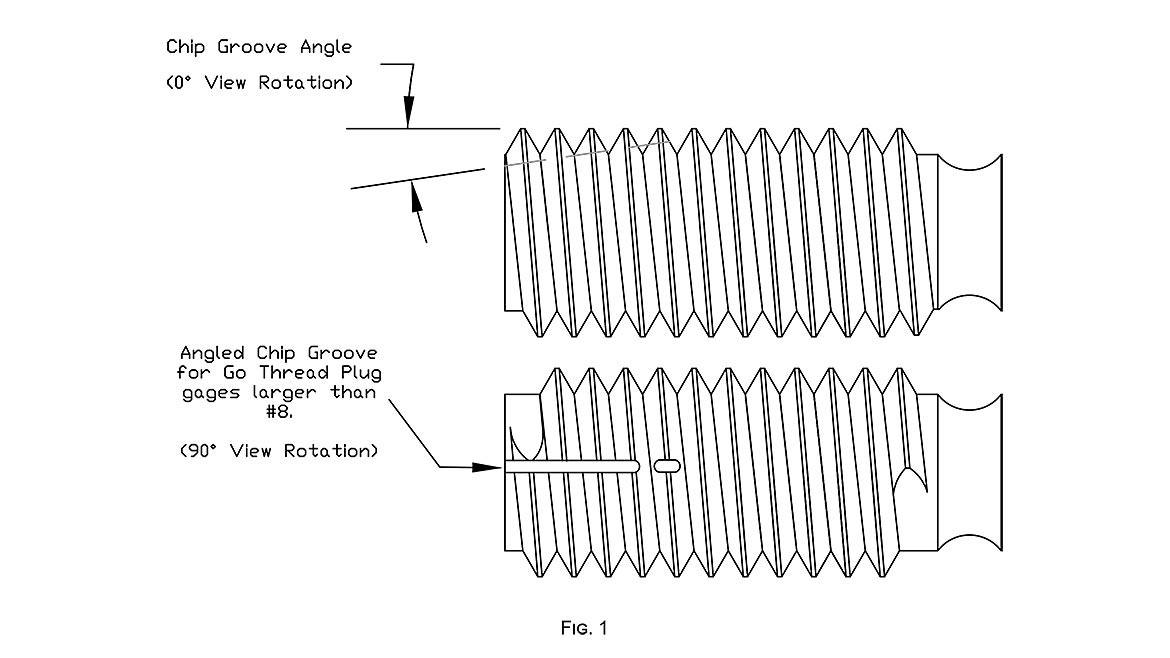

Chip Groove:

Chip grooves are a ground angular or straight slot, ground below the root of the thread on the starting end that is applied to many GO thread plug gages. The purpose of the chip groove is to create a clearance space for foreign material from the manufacturing process of the part thread to accumulate without impeding the function of the gage. The chip groove does not allow the inspection of dirty threads or threads full of grinding swarth, burrs or chips from the part manufacturing process.

According to ASME B1.2, pg. 13, para. 4.1.11, "Each GO thread plug gage, except in sizes No. 8 (0.164 in.) and smaller, shall be provided with a chip groove at the entering end." "The groove shall be located circumferentially at the start of the full thread, and in all cases the depth shall extend below the root of the first full thread." See ASME B1.2-1983, pg. 13, Table 3 for the recommended widths for chip grooves. (ASME B1.2-1983, pg. 14, FIG. 2 has an illustration of the end view of a GO thread gage with a chip groove.) In some cases, the chip groove may need to be altered or removed. Customers who use automated gaging tools on machining centers where the GO gage is fixtured on a machine tool holder may have problems with cross-threading or other damage to their parts during the automated inspection. If the machining center does not rotate the gage to ensure the thread start on the gage aligns with thread start on the part thread before rotating the GO gage into the part, the chip groove can grab the internal part thread. The sharp edge of the chip groove may damage the part thread. Creating a program that allows for the reversal of the thread with slight pressure to ensure that the thread lead on both the part and the gage are aligned will greatly reduce this issue. Some customers prefer to use gages without the chip groove on the GO thread plug gage when used on automated inspection tools. Cross-threading is still an issue but, with a little programing this issue may be reduced when the chip groove is not present on the GO thread plug gage. Another area to be cautious about is soft or ductile materials such as plastics and nylon. The soft materials are easily damaged if the gage user is not careful when using the GO member with the chip groove. The chip groove can work like a cutting tool and damage the soft part thread. This becomes a much bigger problem when inspecting parts made from expensive materials such as gold or platinum, or in expensive highly detailed parts with multiple holes and other features. Having to rework a new aluminum engine block due to one damaged thread is very expensive and frustrating.

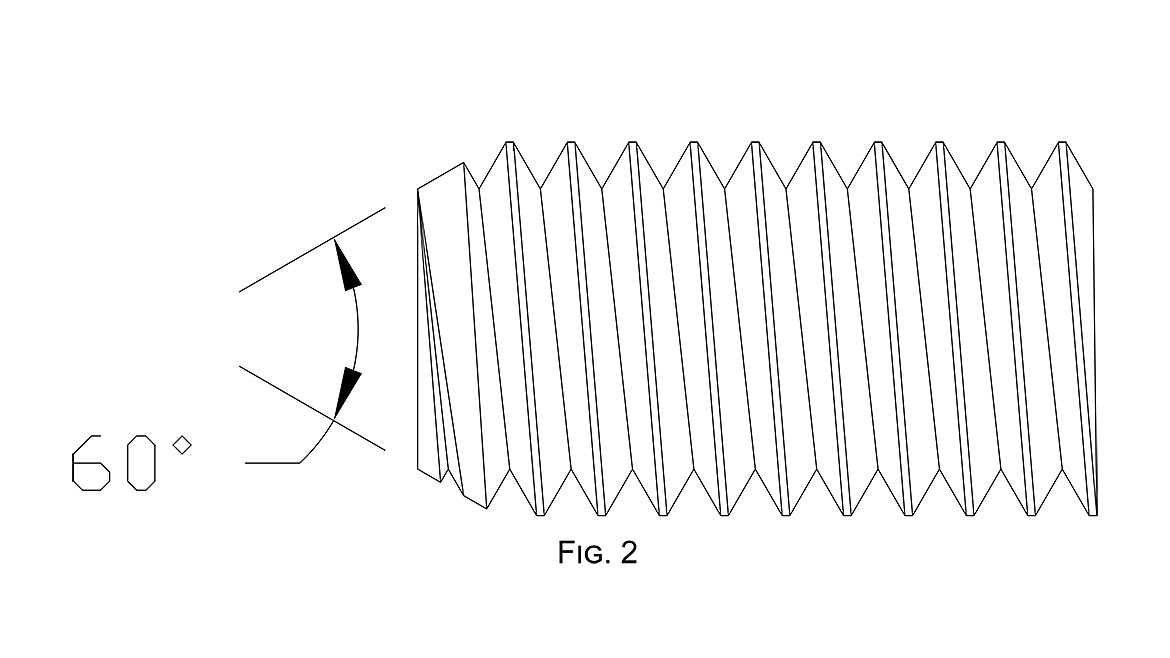

Chamfered Threads:

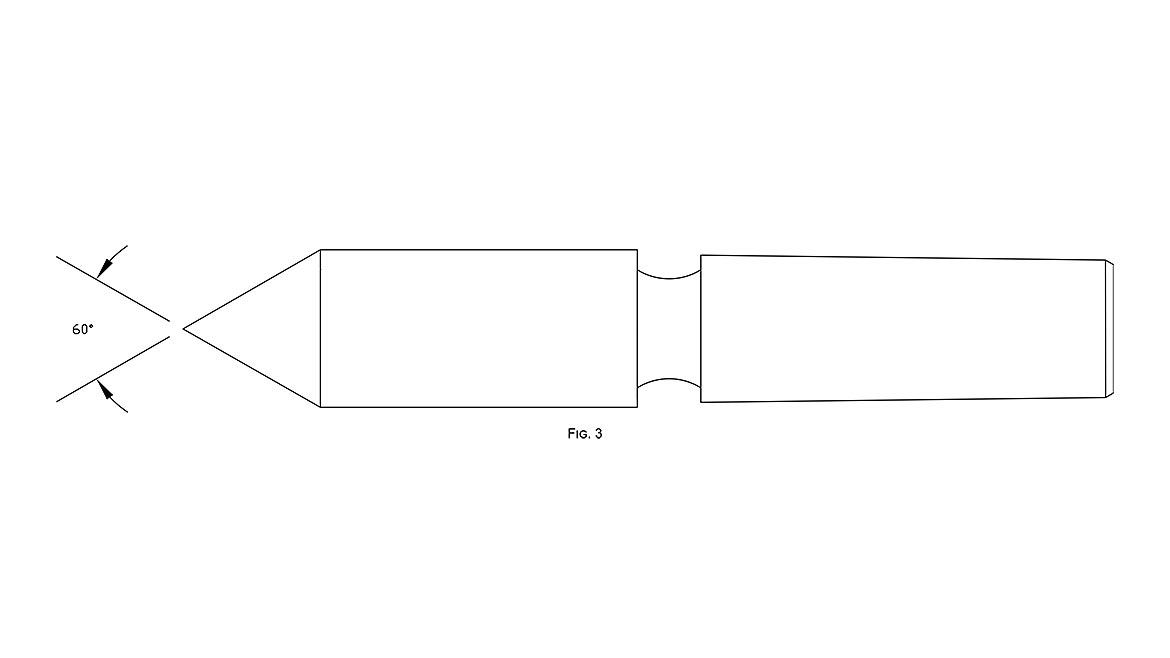

A 60° conical chamfer will be found on thread plug gages 28 TPI (Threads per inch) and finer (28, 32, 40, …). In Fig. 2 you can see the incomplete thread run out on the 60° chamfer on the front of the part. According to ASME B1.2-1983, pg. 14, para. 4.2.10 "Incomplete Thread", "On pitches 28 threads / in. and finer, a 60 deg. chamfer from the axis of the gage is acceptable in lieu of a blunt start." These finer pitch threads will usually have a 60° male center on thread blanks for smaller diameter thread plug gages. (See Fig. 3.) No. 0 (over 0.059") to No. 6 (to and including 0.105") nominal thread diameters. (See ASME B47.1-2007 for more information on the taper-lock thread blank design.)

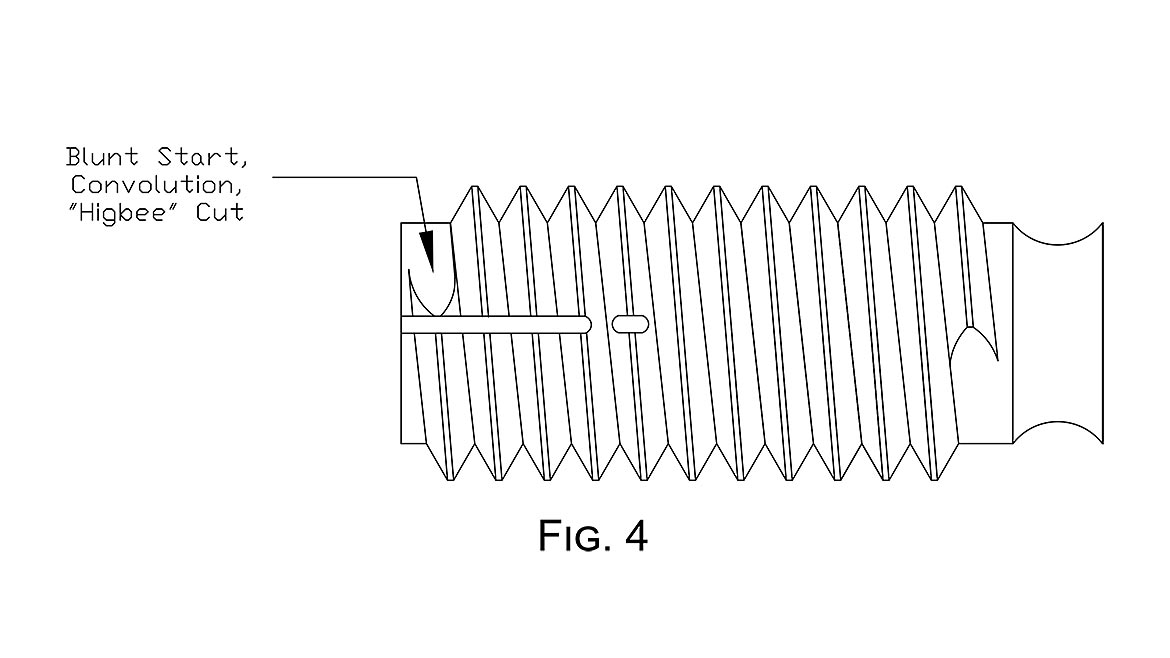

Convolution, Blunt Start Thread, & "Higbee cut":

The previously mentioned "Higbee cut" may be found in the ASME B1.7-2006, pg. 3 under the "Blunt Start Thread" definition. "Blunt start thread: a thread with the removal of the incomplete thread at the starting end." The final sentence of the definition states: "Also known as Higbee cut or a convoluted thread." The ASME B1.2-1983, pg. 14 para. 4.2.10 "Incomplete Thread" states, "The feathered edge at both ends of the threaded section of the gaging member shall be removed. On pitches coarser than 28 threads / in., not more than one complete turn of the end threads shall be removed to obtain a full-thread blunt start." Fig. 4 shows an illustration of the Convoluted, Blunt Start, Higbee Cut thread. This convolution intersects the chip groove at the first full thread as shown.

When a thread is cut or ground and runs out beyond the end of the plug gage, a feathered razor-sharp thread may be created. If this feathered sharp thread is not removed, it can damage the part being inspected or roll a burr into the gage thread form and prevent the gage from starting in the part to be inspected. In some cases, this may also be a safety issue. If not removed, this sharp thread has the potential to cut into an operator’s or inspector’s hand as well as a part.

The three terms discussed in this article tie directly to other features and thread inspection challenges. Small thread gages made with male centers (60° Point) may cause issues when measuring blind threaded holes. In this case the gage user may need to order a gage that as the point ground off or "Blunted" (not to be confused with "Blunt Start Thread"). GO thread plug gages that have depth notches applied may require the face of the convoluted GO thread plug gage ground to within ½ a Pitch of the first full thread. This ensures the ability of the user to measure the full "functional" thread depth.

Thread gages and threaded products have a language all their own. Understanding the terms and the nomenclature associated with them will help us to better use the gage as it is designed. This leads to the manufacture of better products and assures the assembly of mating parts.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!