Automation

How Automation Can Help You Achieve Your Growth Targets

The work that employees enjoy least is generally the most suitable for automation.

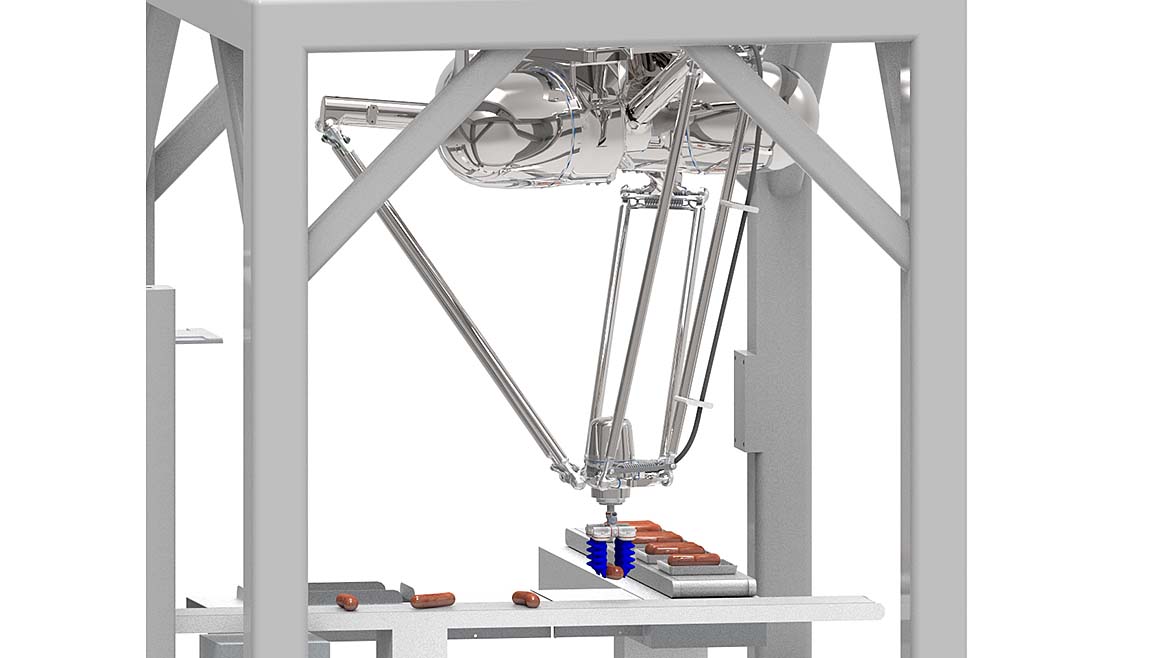

All Images Source: FANUC America

For any business, determining the right path towards achieving growth targets often keeps managers awake at night. Key goals include finding skilled labor to handle the workload and having the revenue on hand to be able to scale operations to adjust to customer demands. Ideally, companies that are in it for the long haul embrace proactive strategies that allow them to meet challenges head on and avoid negative outcomes that impact the bottom line.

Reconsider 100% Manual Operations

When your company is just starting out you likely have a small team of employees that tackle everything on their own. As business expands, it’s a good time to reconsider 100% manual operations and invest in automation for one or more processes. First off, with an increasing shortage of available labor it’s difficult to find employees, and once they are on board, it can often be hard to get them to stay.

Another major pain point that can prompt you to automate is not being able to keep up with demand. Having more physical demand for your business’s products can be a good problem to have, but not if you’re unable meet that demand. The consequences can make or break your future profits, as you’ll not only lose out on potential revenue, but even worse you’ll lose your customers’ trust, and they will go elsewhere, which translates to lost sales. Companies that embrace flexible automation will be better equipped to meet customer demands and grow the business without a heavy financial burden.

What’s the Return on Investment for Robotics?

If you’re new to automation and considering robots for the first time, it’s a good idea to take the time to develop an automation strategy based on the competitive advantages that automation can bring to your organization. Determining the ROI for robots and automation includes evaluating the key financial benefits plus other advantages like enhanced process quality and improved reliability.

So, it’s evident that the benefits/ROI of process automation will vary from company to company. One certainty is that automation is inherently going to help your business if it’s integrated properly, bought at the right price, and implemented at the right time.

Efficiency is the Name of the Game

When it comes to implementing automation, efficiency is the name of the game. More specifically, robotic process automation can run for three shifts, seven days a week, all year long, which is a recipe for maximum efficiency. The processing time alone is much faster than manual operation, not to mention improved accuracy by removing the chance of human error.

In terms of efficiency, it’s likely that the most important aspect is data collection. As part of Industry 4.0, a key advantage is the ability to monitor and record the jobs performed by an automated system. Process audits of the data collected from a robot or other automation equipment provide companies with access to real time critical data that helps them make continuous improvements, reduce costs, and stay competitive.

Meeting Regulatory Standards

If your business is in an industry that requires maintaining certain regulatory standards, then robotic automation can help you get and stay compliant with those regulations and have better control over your process. Your audit trail will always be accurate as you record your process activity. Eliminating compliance issues will boost your reputation and give your customers the peace of mind that they are working with a company that prioritizes their needs.

Improved Employee Satisfaction and Retention

The work that employees enjoy least is generally the most suitable for automation. Once people are relieved from performing undesirable tasks, they can focus on more rewarding jobs that require human skills. Robotic automation ;truly transforms a person’s job when they can go from transferring, handling, or packing products, to managing the robots and automation to do those often dull, dirty, or dangerous tasks. And for employees who will work with robotics and automation, it’s critical to help them upskill by sending them to a local school or training center that provides certified automation training.

Employees who are challenged to think creatively and critically feel a bigger sense of purpose. Inevitably, this will increase morale, efficiency, and even boost productivity.

Automate When It Makes Sense

An automated robotic workforce can be whatever size you need it to be depending on your customers’ demands. As your business evolves, higher demands require faster processing of goods and services.

So, whether you’re just starting out or trying to rebuild an existing business, the time is right to consider automation. Gather your team together and hold ideation sessions to determine where robotics and automation will make the most sense. Using a strategic and comprehensive approach to identify important value drivers for your organization allows you to build a strong business case for automation.

When you’re ready to automate, we are here to help you move away from labor-intensive production to a cost-effective automated solution. Once you invest in robotic automation, you’ll be prepared to expand/scale your business to achieve growth targets and improve your competitive position.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!