Quality Plant of the Year Winner

2023 Quality Plant of the Year: Reed Switch Developments

The annual Quality Plant of the Year has a strong past and a bright future.

All Images Source: Reed Switch Developments

Watching your mom solder magnetic reed switches at the dining room table leaves a lasting impression. So does playing at the plant as a kid on weekends. These memories make family small business ownership seem like fun. In any case, they might pique your interest in manufacturing.

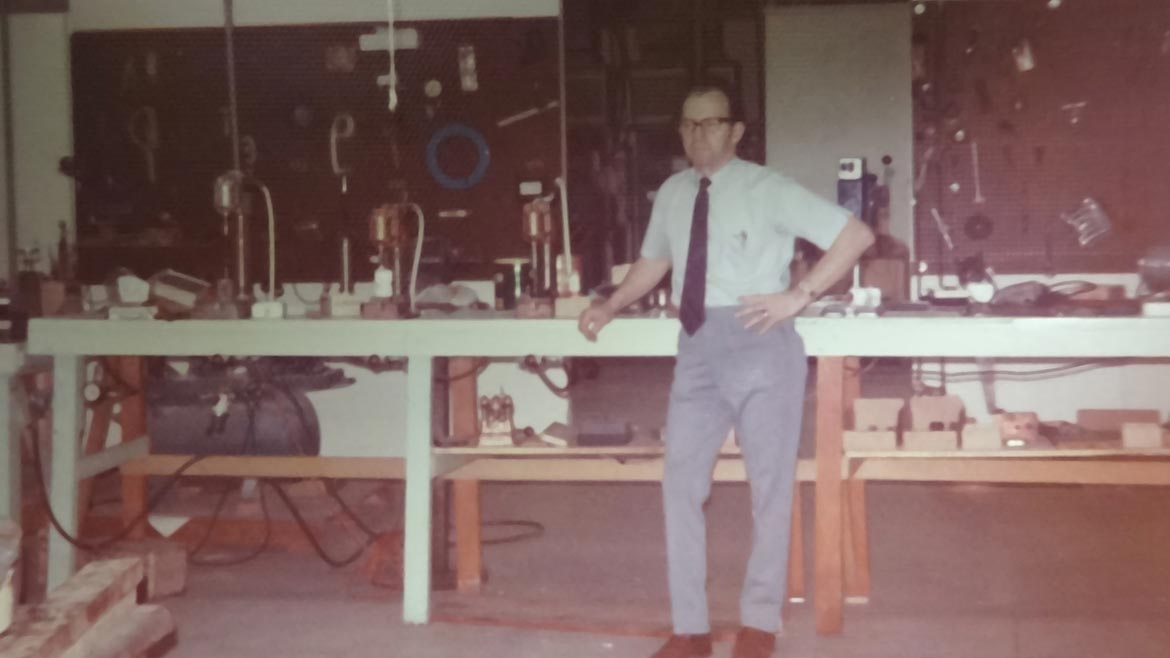

Debra Dahlin still remembers seeing her mom, hair in curlers, soldering magnetic reed switches at the dining room table as she left for school. At the same time, she recalls her father taking the whole family along to work on weekends. The family business eventually made its way out of the basement and dining room, into a shared industrial complex, and then later into its own free-standing facility.

Today, Dahlin is the second-generation owner and president of the WBE-certified Reed Switch Developments Corp. (RSD). Under her leadership, RSD has grown steadily, despite a series of recessions, a global pandemic, and a major pivot from primarily standard parts into small-to-medium volume custom ones.

Article Index:

The company, based in Racine, WI, celebrated its 55th anniversary last year, alongside its 35th as a Wisconsin manufacturer. It did so while also achieving its highest-ever company sales and best-ever quality metrics. These milestones were formally recognized by several letters of commendation, including one from United States Congressman Bryan Steil, the now-Chairman of the Committee on House Administration.

For its commitments to quality, training, and growth, Reed Switch Developments Corp. is our 2023 Quality Plant of the Year.

Celebrating History

The company’s story begins in the Dahlin family basement. It was there that Debra Dahlin’s late father, Harold, and his business partner John Hammond, started Reed Switch Developments Corp. Dahlin, the company's second-generation family owner and president, joined the company shortly before graduating college with a marketing degree. Under her leadership, RSD has continued to grow and evolve. Continuous quality and process improvements, including a willingness to try new things, branch out into other applications, and to make investments in expert resources and technologies, have helped RSD to effectively weather challenges along the way.

Lean training, which started in 1999, has made a difference to the company’s quality operations as well. “It kind of blew us away,” says Dahlin. Through training with the Wisconsin Manufacturing Extension Partnership (WMEP) program, RSD first learned how to tangibly improve productivity.

“Even though we do lower volume or custom one-off parts, it was still possible to standardize our processes. That made a believer out of me,” she says. “We’re willing to try just about any new process in order to be adaptable and flexible.”

Dahlin’s leadership also included the addition of outsourced industry talent, brought in specifically to expand and help modernize the company’s sales and marketing operations. In 2014, Dahlin added fellow WBE Molly Bakewell Chamberlin of Embassy Global, LLC, to serve as the company’s fractional CMO and business development advisor. Since then, RSD has achieved ongoing measurable sales growth, including an additional $1.1 million in new sales in 2022, and with another $500k in new customer business already in the pipeline for 2023. Via this approach, Dahlin has added expertise to maximize profitability, expand RSD’s global footprint, and yet still streamline overhead costs.

Maintaining Quality All The Way

As part of its continued commitment to quality, RSD continues to invest in new technologies. “While we have a rich history, we also feel that we have a very bright future,” says Jeff Rosenbaum, engineering/QA coordinator, “and we find that adapting to current technology trends helps us stay competitive, including on a world stage where we are becoming increasingly better known.”

Long-time customers also appreciate working with Reed Switch Developments Corp. Jim Cota is a buyer at LDPI, a manufacturer of hazardous fluorescent lighting fixtures and new lighting applications. The company has been an RSD customer since May 1999. In his role for LDPI, Cota purchases production components and materials. RSD provides LDPI with a custom magnetic reed switch. “LDPI has been using this switch for over 20 years,” Cota says. “There have been few changes over time. Pricing, quality, and on time delivery have all been consistently good.”

Blending Tradition And New Ideas

Dahlin is most proud of the company’s core values of ingenuity, quality and adaptability, all of which have allowed RSD to address each new challenge successfully.

“Any challenge that’s been presented to us, including several recessions, the pandemic, the Great Recession, doesn’t beat us down,” Dahlin says. Back in 1990, for example, amid a slower economy, customers began asking about their capabilities to produce one-off or smaller volume custom parts. Previously, RSD would have declined such projects. “But instead, we began to ask ourselves, “Why aren’t we, why can’t we, why shouldn’t we, and how can we produce them?”

How to Adapt to the Times: Advice from our 2023 Plant of the Year

Debra Dahlin, CEO of Reed Switch Developments Corp. has lead the company through a series of challenges and changing business conditions. She offers some advice for other manufacturers on how to adapt to industry trends, whether it is through Lean, new marketing initiatives, or employee suggestions.

“That opened a new door,” Dahlin says. “We found that we began to pivot from primarily off-the-shelf products into smaller volume and one-off custom applications.”

“We chose to listen closely to the evolving needs of our customers and to evolve our company to meet those needs. You don’t know what you can achieve if you don’t try,” Dahlin says. This spirit of proactive continuous improvement is also instilled into every RSD employee, as they are trained to constantly ask, “Is there a better way to do this?”

Dahlin enjoys watching new employees bring fresh ideas to the table. Otherwise, she notes, there is a risk of getting tunnel vision. When employees ask, “Why are we doing it this way?” it’s possible to hear ideas that haven’t occurred to anyone before.

Brenda Mroch, lean initiatives coordinator/production manager, agrees. She believes that fresh eyes tend to bring new ideas. Mroch stresses that RSD employees are trained to think of the next process/operator as their internal customer. This mindset ensures RSD products are made to the highest quality standards for its external customers.

Dahlin points out that tangible success has come from Mroch’s approaches to quality, given that in the five years since Mroch has been with the company, the internal rejection rate continues to drop each year.

Building For Success

When RSD decided in 2004 that it needed more space, Dahlin had to decide between designing a new building or finding an existing one. The company ultimately decided to build a brand-new facility. The design was spearheaded by Debra’s brother, the national award winning architect Ken Dahlin of Genesis Architecture. The overall building theme was an open office environment for increased collaboration.

Article Index:

This theme extended into the production floor, with a setup that allowed for a more flexible manufacturing environment. The new building had no hard electrical or communication wiring, only moveable drops. The drops enabled RSD to freely move equipment and reconfigure the production floor on an as-needed basis, to flexibly accommodate increasing automation requirements.

“During my first initial walk through with Debra, I was blown away by her foresight with the production floor layout being so adaptable to implement continuous improvement and the lean principles,” Mroch says.

“As a result, when RSD did its recent Kaizen event, rearranging the entire production floor could be done efficiently,” says Mroch. RSD further implemented Kanban on the floor for point of use, allowing operators to pull parts more easily for orders and improve workflow.

“All of that illustrates how proactive we are about everything,” says Rosenbaum. “We always try to think beyond today, in terms of how flexible and adaptable any prospective new piece of equipment will be. When it comes to our decisions to invest in new equipment, we will typically spend a little more upfront to gain added flexibility. More than once, that approach has helped us in the long run, where we didn’t anticipate needing some feature or benefit that later we found we did, and were covered by our proactivity.” He says that foresight is one of Dahlin’s many leadership strengths: “She is never just thinking about today.”

When asked about its current quality challenges, the team immediately mentioned the lessened market availability of raw materials. Despite the difficulties, RSD has been able to adapt, including at times perhaps by using another material, or finding a new strategy.

“In a number of cases, we were able to expand our customer base, since some of our competitors at times cannot be as agile at creatively addressing supply chain issues,” Rosenbaum says. “Part of that for us is our exceptionally talented purchasing person.” Another factor is: “we take a little bit of risk, we buy what we need, then buy a little more.”

“Under normal circumstances, most of our products have a two-week lead time. There are exceptions, of course, though we have managed to maintain excellent lead times in the post-COVID environment. We not only have been able to continue on, we have thrived.”

Finding Solutions Together

Rosenbaum recalled a customer quality situation that arose shortly after he started with RSD. A longtime customer had started having an incredible amount of returns. RSD kept assuming that it was its own internal quality issue. Each time that a shipment would be sent, a high percentage would be returned. RSD began to analyze in-house processes and speak to operators in order to verify first-hand what the customer was experiencing. In doing so, they found new areas for internal improvement, including product traceability. After a top-down analysis, they asked to do a walk-through at the customer site. In that effort, the customer found areas where they could improve as well. Today, the customer remains one of RSD’s largest.

“It was a crash course for me, baptism by fire in the manufacturing realm, when I started here,” says Rosenbaum, who initially came from an IT background. “It taught me a lot as an individual.” He noted that he had to learn things that his coworkers already knew, such as lean and ISO concepts. “It illustrates how much success you can have when you choose to partner with your customers. It doesn’t do any good to point fingers when things go wrong. We’re open to the fact that we might need improvements, and also look at ways to help improve things on the customer’s end as well.”

Rosenbaum noted that the two most common product failure modes are physical shock or electrical damage, neither of which can be diagnosed from mere visual inspection.

Shaping The Future

The company is constantly evaluating new technologies, and automation and new technology integration initiatives are ongoing. They’ve been using 3D printing for several years, and recently, the company added in-house CNC capabilities, which has helped with internal production as well as rapid prototyping. RSD also began to incorporate some factory floor robotics.

The first 56 years of Reed Switch Developments Corp. have been a success. With the current environment, it looks as if the next 56 years will be as well.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!