NDT | Certification

Certification Records for Nondestructive Testing (NDT) Personnel

Before an individual can become certified in an NDT method, a number of prerequisites must be fulfilled.

Image source: Getty Images

The information presented herein is intended to be of a general nature and so can be applied to most employer-based certification programs. It is intended for those who may not have a great deal of familiarity with the nuances of NDT certification records or programs.

Nondestructive testing (NDT, aka NDI, NDE) personnel in the United States are commonly certified in accordance with an industry specific requirement. For example, aircraft and aerospace organizations typically specify NAS 410, operating nuclear power facility regulations specify ANSI/ASNT CP-189 as modified by ASME Section XI, most other general industries fall under SNT-TC-1A and there are a number of blended and specialized requirements for specific applications. Virtually all of the above operate under some level of oversight by upper tier vendors and/or regulators.

Therefore, most individuals involved in the certification of NDT personnel, regardless of particular industry or governing code requirement, will have their personnel certification files audited at some point. This article is intended to impart some suggestions to help reduce or eliminate common pitfalls and to illustrate some standard industry good practices in assembling and maintaining these files.

Before an individual can become certified in an NDT method, a number of prerequisites must be fulfilled. They must have successfully completed the required number of hours of formal classroom training and accumulated the required number of hours of hands-on experience in the method in which they are becoming certified and also the total number of hours in NDT.

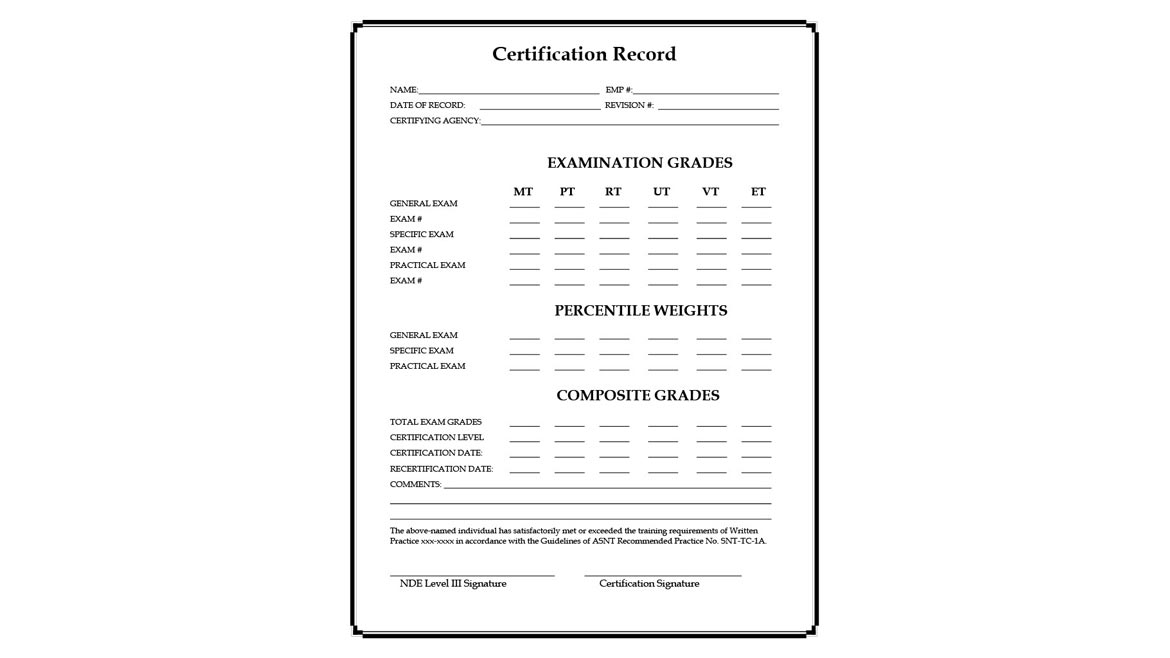

Sample Certificate Image source: Source: NIC

They will then be required to pass the written general (closed book), written specific (closed book except for applicable references), and hands-on practical examinations and demonstrate acceptable visual acuity and color-contrast vision capability. Once all of these elements have been properly administered, verified and documented, a certification record can be issued.

If the individual is new to NDT and is gaining all of their training and experience within the employers’ organization, the process is rather straightforward – typically the individual would progress through the stages of being an NDT trainee, then Level I, Level II, etc. Records of ongoing training and experience hours in each NDT method would simply be maintained in accordance with the employers’ written practice.

Frequently however, personnel with previous training and experience and/or prior employer certification in NDT are hired. The Level III must carefully scrutinize records of previous training and experience to verify their validity if they are to be used as a basis for certification.

Training records should include the number of hours and content, evidence of successful completion of a course examination and the name/signature of the qualified instructor. Previous employer’s certification records sometimes include a summary of all of the training received by the employee throughout his/her career – it is not considered good practice to solely count the hours listed therein, especially those from prior employers, as acceptable documentation of training.

Experience records should list hours relevant to the applicable NDT method and, if applicable, that the hours for initial certification were gained under the supervision of a certified Level II or III. It is a good practice to verify previous training and experience hours with the prior employer(s) – some standards require that this be done.

Examinations should be legible - any corrections made by the examinee or the examiner should be lined-through, initialed and dated. They must contain the proper number of questions as specified in the written practice. It is advisable to add a few additional questions beyond the required minimum number in case a question is disputed as a repeat or as non-relevant to the method.Specific examinations should address the work and codes used by the employer. Some auditors may not accept questions that are simply “look-up” type questions so it is best to have items that require application of knowledge or comprehension of the method, process or procedure. One way to address this is to have questions based on the acceptance criteria where the examinee is required to perform an interpretation.

Practical examinations should include a ten-point checklist, a description of the test specimen(s) and the procedure used to conduct the examination. Documentation should include evidence that all discontinuities and conditions specified by the Level III were detected. Test samples or coupons should be stored with access restricted to appropriate personnel and should include documented validation of test results by a Level III.

All examinations should have documented approval of the Level III and completed exams should be signed by the Level III or by a qualified and approved delegate. Practical examinations must be administered by a Level III in the applicable method.

Visual acuity examinations should be conducted by personnel trained and authorized per the written practice and cover all aspects of the governing standard for near distance acuity (and far distance acuity if required) and color contrast perception. A common pitfall is failing to address testing for shades of grey discrimination when applicable.

Current examinations are required to be on file. Prior to filing, examinations should be checked to verify that scores were calculated correctly and that the minimum test scores and composite scores are in accordance with the written practice.

Annual visual acuity updates and periodic proficiency or technical performance evaluations are required in accordance with the written practice. It is advisable to track these due dates in a reliable manner in order to ensure that personnel do not perform NDT under a suspended or expired certification status. Commercial programs are available for this tracking but depending on the number of personnel and size of the organization a simple calendar or spreadsheet program may suffice.

The methods of filing, storage and maintenance of personnel certification records should be detailed in the written practice and/or quality program documents to ensure that record retention times, document protection and retrievability requirements are adhered to. These records should be controlled with access limited to appropriate personnel.

When presenting records storage facilities during an audit, first impressions are important. Typically, files are stored in cabinets in hanging folders with manila subfolders separating the resume, visual acuity, training, experience and examination records, etc. Some organizations prefer placing records in binders or two-hole punched expanding folders. While more cumbersome if frequent individual record retrieval is required, this is usually viewed a more secure and organized system of record keeping.

It should be noted that even though an outside Level III agency may be retained to help develop and administer examinations to the employers’ personnel, the employer is left with the responsibility of maintaining those records and will likely be responsible for demonstrating compliance during audits.

Final cautionary note - certain standards have specific and stringent requirements over-and-above the basics discussed here. The reader is strongly encouraged to determine all of the requirements applicable to the industry they serve.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!