Better Machine Vision: The Benefits of Combining 2D and 3D (Part Two)

Haven't read Part One yet? Read it here!

Combining 2D and 3D Technology

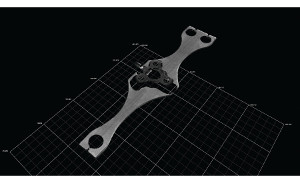

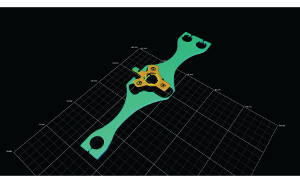

3D builds on the proven capabilities of 2D by adding a secondary layer of data describing shape, which is essential to designing highly robust measurement systems.

The Benefits of 3D

Richer Data Acquisition

3D measurement produces shape information that 2D systems do not. As a result, features related to shape can be measured such as object flatness, surface angle and volume.

Measurement Stability

All components in 3D sensor are rigidly mounted on a single opto-mechanical assembly to ensure repeatability, with focal lengths locked in place relative to emitter and imager planes, and temperature compensation included for correcting movement due to metal creep.

Precision and Repeatability

With the depth measurement information provided by 3D machine vision, errors due to object location (distance from the sensor) are no longer possible—meaning objects can move anywhere within the sensor’s measurement volume and still yield accurate results. This simplifies object fixturing requirements and reduces both system design and maintenance costs.

Multi-Sensor Stitching

A further benefit of 3D machine vision is the ability to stitch together 3D point clouds from relatively few multiple scanners calibrated to a common coordinate system using a known artifact. For example, a large object such as a truck frame can be scanned with multiple scanners. Locating and aligning hundreds of 2D cameras and using photogrammetry to produce 3D models is far more complicated and less accurate than using a small number of highly accurate 3D scanners.

Precision Robotic Guidance

Industrial robots work in a three dimensional world. A blind robot is limited to performing repetitive and structured tasks. 3D machine vision allows a robot to sense variations in its physical environment and adapt accordingly, increasing flexibility, utility and speed in essential applications such as pick-and-place.

WHY 3D MACHINE VISION?

- Contrast invariant, ideal for inspecting low contrast objects

- Volumetric measurement (X,Y, and Z-axis) provides shape and position

- related parameters

- Insensitive to minor lighting variation or ambient light

- Higher repeatability due to integrated optics, lighting, and calibration

- Simpler to build multi-sensor setups for large object inspection

Stay tuned for Part 3 on Combining 2D and 3D