Vision & Sensors

Vision & Sensors | Vision & Sensors 101

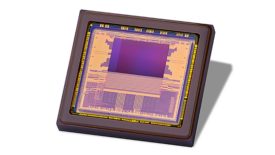

The push towards miniaturization is reshaping numerous industries, influencing design decisions and fostering innovation.

Read More

Vision & Sensors | Machine Vision 101

Part 1: AI and Machine Vision Lenses: Enhancements, Trends, and Evolution

The importance of quality image acquisition cannot be stressed enough.

November 14, 2023

Machine Vision Systems

Machine Vision for Battery Production 4.0

Machine vision has increasingly established itself as an indispensable technology for companies in a wide range of industries.

November 13, 2023

Vision & Sensors | Robotics

What You Need to Know About Robot Safety Standards

A Q&A with A3’s Carole Franklin

November 13, 2023

Vision & Sensors | Trends

Machine Learning and Artificial Intelligence Tools: The Benefits, How They Work, and Avoiding Common Pitfalls

Dive into the world of artificial intelligence (AI) and machine learning and learn how to deploy and maintain this evolving technology.

November 7, 2023

Vision & Sensors | Vision

How Robotics Applications Benefit from Machine Vision Lighting Advances

Innovations in illumination create new opportunities in automotive manufacturing, food processing, and warehousing.

November 6, 2023

Measurement

Why More Manufacturers Should Consider Implementing a Vision Measurement System

Technology advancements, emerging industries, and congressional legislation point to an exciting future for vision measurement systems.

October 18, 2023

Vision & Sensors | Machine Vision 101

Automation - Quality Practices Can Determine Next Step

Those quality practices can determine if your next step will be a rock or an alligator.

September 10, 2023

Vision & Sensors | Machine Vision 101

Smart Manufacturing Approaches to Automation

The ultimate goal for digital transformation is improved quality.

September 7, 2023

Vision & Sensors | Sensors

Unleashing Potential: How Advances in 3D Vision Sensors are Transforming Manufacturing and Logistics

Manufacturers can rely on sophisticated sensors to revolutionize the way they do business, enabling enhanced quality control, improved efficiency, and increased safety.

September 4, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing